特点介绍:

1、标配双合金螺杆料筒,更加耐磨、耐腐蚀,提高使用寿命,主要适配回料生产。

Double alloy screw barrel is standard,which is more wear-resistant and corrosion-resistant.

improves service life.and is mainlysuitable for recycling production.

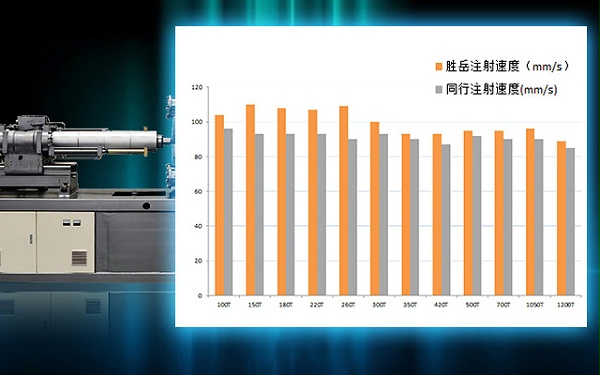

2、标配数控背压阀。加大的动力系统,射胶速度更快,缩短成产周期,提高生产效率。

Numerical control backpressure valve is standard. Enlarging the power system,

the injection speed is faster.the productioncycle is shortened,and the production efficiency is improved.

3、全新刚性机架,减震更加明显,生产更稳定。

New rigid frame.more obvious shock absorption and more stable production.

4、加热可选配纳米红外节能加热装置,能量损失小、加热质量高。

Nano infrared energy-saving heating device can be selected for heating,with small energy loss and high heating quality.

| 技术參数 SPECIFICATION |

ZG380/IU2800 |

ZG470/IU4000 |

ZG530/IU4400 |

ZG530S/IU6200 |

ZG600/IU6200 |

||||||

| 注射部份 INJECTION UNIT |

B |

B |

B |

B |

B |

||||||

| 注射容积 Shot Weight | cm3 | 2270 | 3261 | 3613 | 4942 | 4942 | |||||

| 注射量(PP回料)Injection Weight | g | 2430 | 3488 | 3866 | 5288 | 5288 | |||||

|

螺杆直径 Screw Diameter |

mm | 85 | 95 | 100 | 110 | 110 | |||||

| 螺杆长径比 Screw L/D Ratio |

Sc |

19 | 19 | 19 | 19 | 19 | |||||

| 对空注射速率 Injection Rate | cm3/s | 688 | 877 | 958 | 1055 | 1055 | |||||

| 注射压力 Injection Pressure | Mpa | 122 | 122 | 122 | 126 | 126 | |||||

| 最大塑化能力(PP回料) Plasticzation Capacity | g/s | 150 | 185 | 215 | 278 | 278 | |||||

| 最大螺杆转速 Max Screw Speed | rpm | 175(250) | 175(210) | 170(210) | 170 | 170 | |||||

| 合模部份 CLAMPING UNIT |

|

|

|

|

|

|

|||||

| 合模力 Clamping Force | Kn | 3800 | 4700 | 5300 | 5300 | 6000 | |||||

| 最大移模行程 Clamping Stroke | mm | 700 | 780 | 850 | 850 | 900 | |||||

| 拉杆内间距 SpaceBetween Tie Bar(WxH) | mm | 730*710 | 820*780 | 840*820 | 840*820 | 910*880 | |||||

| 最大模板距离 Max. Daylight | mm | 1450 | 1580 | 1700 | 1700 | 1800 | |||||

| 最大容模厚度 Max. Mold Height | mm | 750 | 800 | 850 | 850 | 900 | |||||

| 最小容模厚度 Min. Mold Height | mm | 250 | 280 | 280 | 280 | 320 | |||||

| 顶出行程 Ejector Stroke | mm | 180 | 220 | 220 | 220 | 260 | |||||

| 最大顶出推力 Ejector Force | Kn | 125 | 152 | 152 | 152 | 182 | |||||

| 电控部份 CONTROL UNIT |

|

|

|

|

|

|

|||||

|

系统压力 Pump Motor Power |

Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | |||||

| 油泵电机功率 Heater Power | Kw | 60 | 43+35 | 55+35 |

65+31 |

65+31 | |||||

|

油泵电机+储料电机功率(选配)Pump Motor Power+Powerof storage motor (optional) |

Kw |

55+53 (一体式直驱) |

65+55 (电机+齿轮箱) |

75+55 (电机+齿轮箱) |

65+31+66 (电机+齿轮箱) |

65+31+66 (电机+齿轮箱) |

|||||

|

电热功率 No.of Heater Control Zone |

Kw | 30 | 40 | 40 | 55 | 55 | |||||

| 温度控制 No.of Heater Control Zone | zone | 5 | 6 | 6 | 6 | 6 | |||||

| 其他 OTHERS |

|

|

|

|

|

|

|||||

| 油箱容量 Oil Tank Capacity | L | 500 | 700 | 700 | 850 | 850 | |||||

| 重量(约) Machine Weight | T | 14 | 18 | 21 | 21.5 | 24 | |||||

| 外型尺 Machine Dimension (LxWxH) | M |

7x1.8x2.4 |

8x1.9x2.4 |

8.6x2x2.4 |

9.2x2x2.4 |

9.7x2.1x2.4 |

|||||

本网站所有技术参数仅供参考,本公司保留修改技术参数的权利,恕不另行通知。All technical parameters of this website are for reference only. The company reserves the right to modify the technical parameters without notice.

高排量的液压系统设计,动力系统加大,注射速度比同类型产品提高15%,模循环周期缩短10-15%,全面提升注塑机表现,可满足高标准的成型要求

油路板分布在各执行元件位置,响应速度快,动态性能好,注塑过程更快速,产品成型更好

注射单元采用模组化的托板座设计,一线式双缸平衡注射装置,使螺杆在注塑过程中受力均匀,显著提高射胶稳定性,使料筒定位更加准确

高刚性的宽模板设计,配合高安全系数的拉杆,整体提升合模结构的刚性及稳定性

伺服驱动器在锁模保压冷却等阶段能输出最大压力但保持速度接近零速,因而功率消耗小,更节能

料筒采用纳米远红外高效节能加热装置,改善了传统加热圈电热转换效率低、热传导率低、表面温度高“两低一高”缺点,比传统加热圈节能30%-40%

控制面板采用彩色屏幕,实时监测生产进程,并显示各种故障诊断,操作更省心

人性化工艺参数设置,设置急停开关,动作全面监控,保护工作人员人身安全